The Link M3 400 Splicer/Roll Stand is a high-speed machine offering flexibility in configuration, installation, machine features, and speeds up to 1500 ft/min.

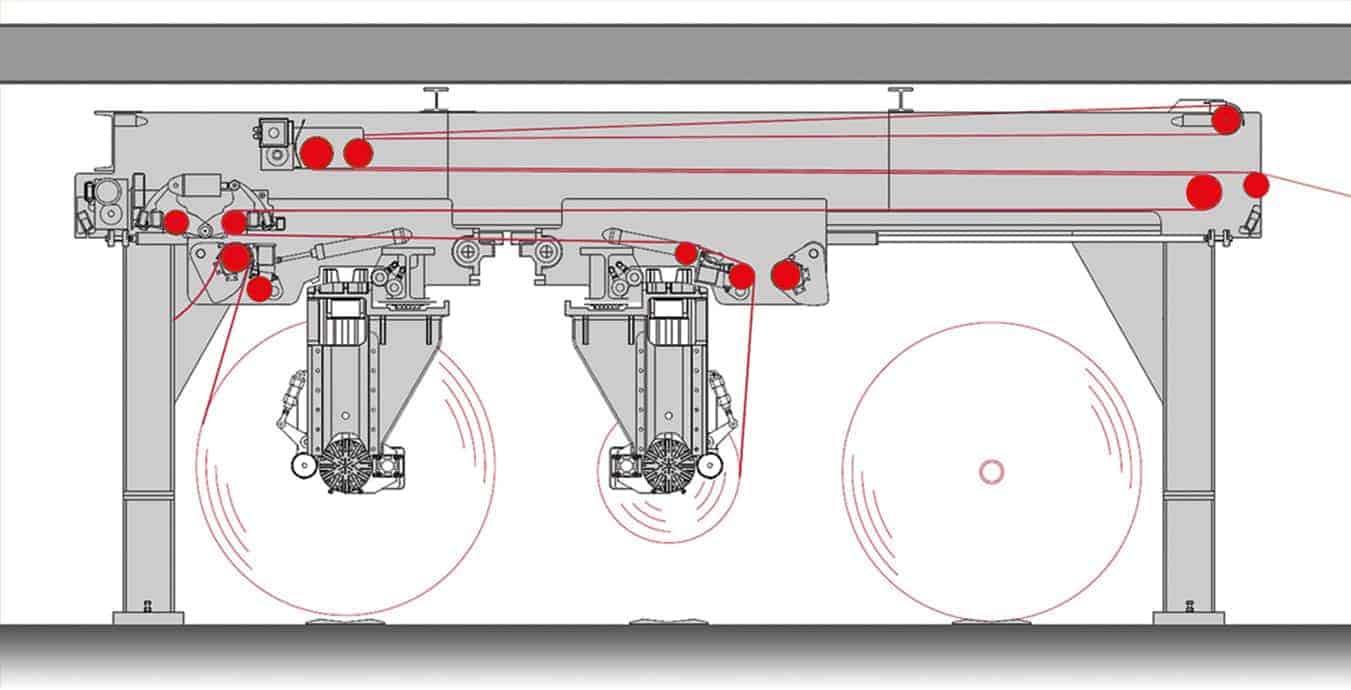

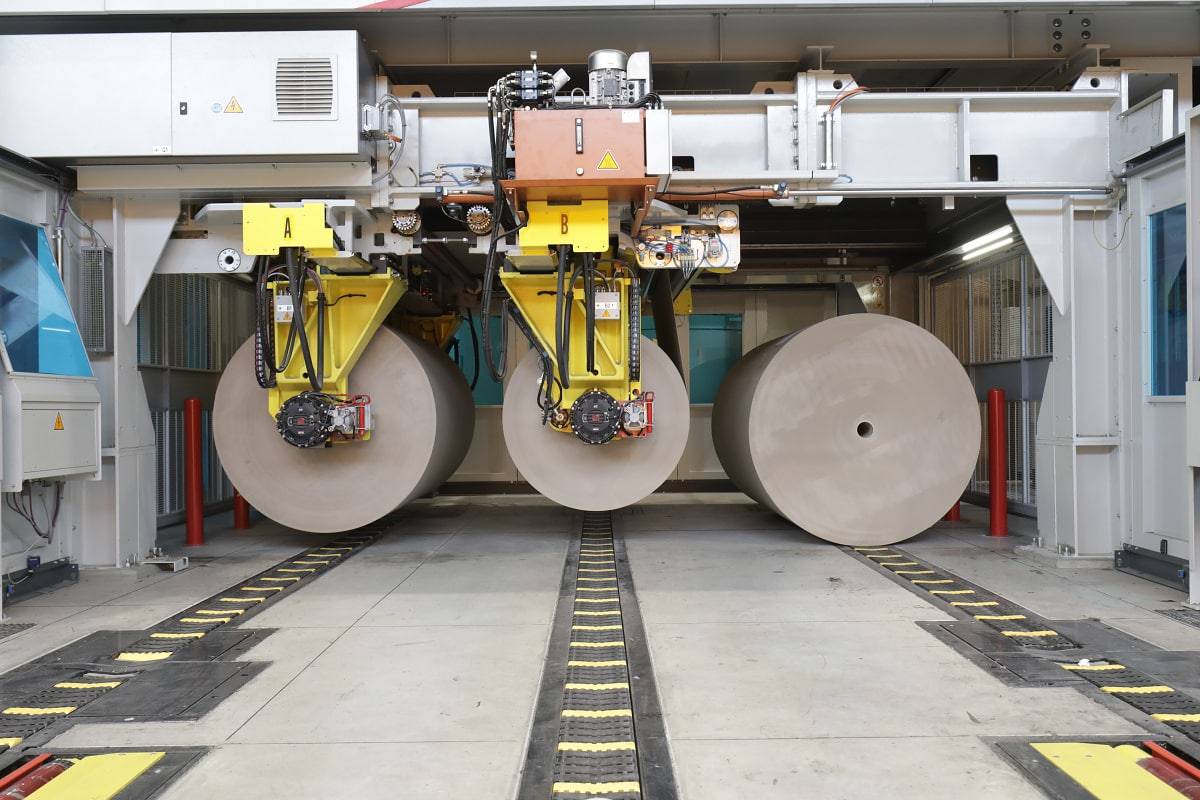

This machine features a triple-roll positioning system that provides the shortest continuous automatic roll change cycle time available in the industry. This machine features a fixed splice prep area and an indexing head truck, which offers more reliable splicing, quicker splice preparation, and eliminates indexing to remove paper slack. Splicing is a simple 2 step air activated sequence, where the A and B sides are activated using the same cylinders. A closed-loop, servo-controlled system provides superior tension control.

The Link M3 400 Splicer/Roll Stand provides the most options for your current needs and allows the maximum flexibility for future modifications or changes to your corrugator.

- Width: 98″ or 110″

- Speed: 1310 ft/min

- Allen-Bradley Electronics

- Intelligent Guard Monitoring

- Roll Cycle Time – 2.5 minutes

- Loading/Unloading Rolls – Operator or Drive Side

- Roll Stand, Roll Delivery, Splicer, and Bridge in One Machine

- Automatic Roll Loading and Unloading

- High Pressure Rolling-Nip Splice Sequence – Zero Tail

- Splice Options:

- Splice Off-the-Core Diameter

- Splice on Entered Roll Diameter

- TailLink – Automatic Splice for Paper Break

- Servo Driven Accelerator Roll

- Dual Roll Festoon with Servo Driven Dancer Roll

Gallery

For more information about the Link M3 400 Roll Stand & Splicer contact your Sales Representative.