ProQuality

ProQuality is Fosber’s defect detection and monitoring system. The system uses a camera system to monitor the singleface web.

The system records and tracks defects in real-time. Defective sheets are diverted at cut-off knife, prior to reaching the stacker and only sellable sheets reach the stacker. The system detects all surface defects such as medium-paper defects, delamination, wrinkles, tears, splice joints, and edge defects.

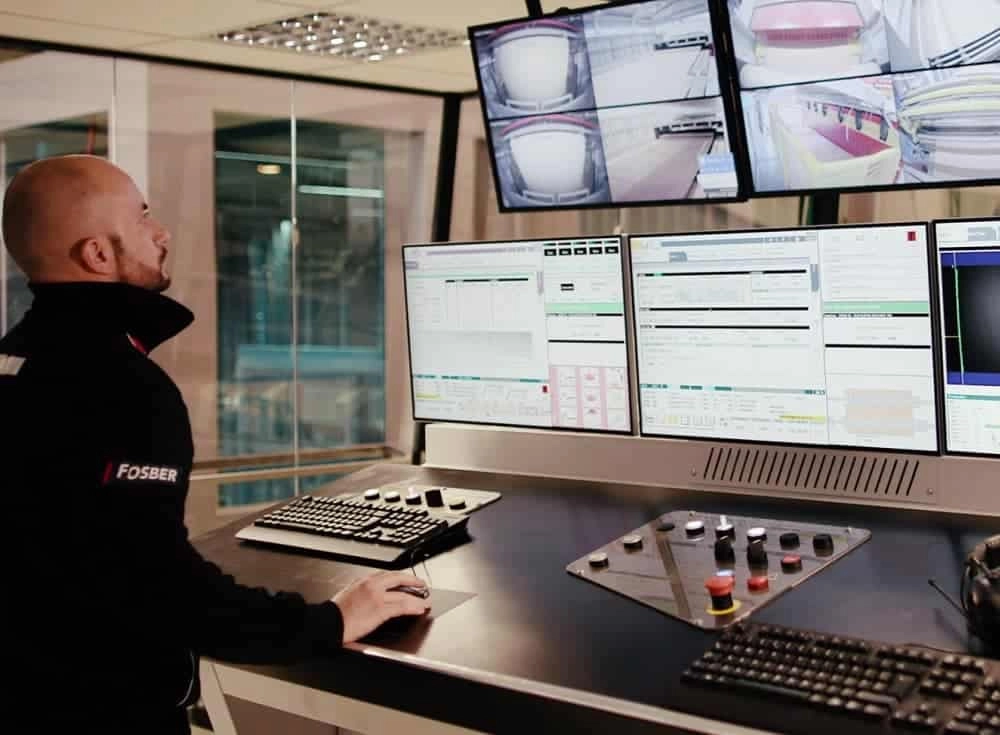

The ProQuality system provides the operator a “captured image” to the corrugator so that only sellable sheets are delivered to the customer.

- Camera Technology

- Detection at SingleFacer

- Automatic Divert of Defect Board at Cut-Off Knife

- Visual of Defects for Operator Review

- History of Defects for Reporting