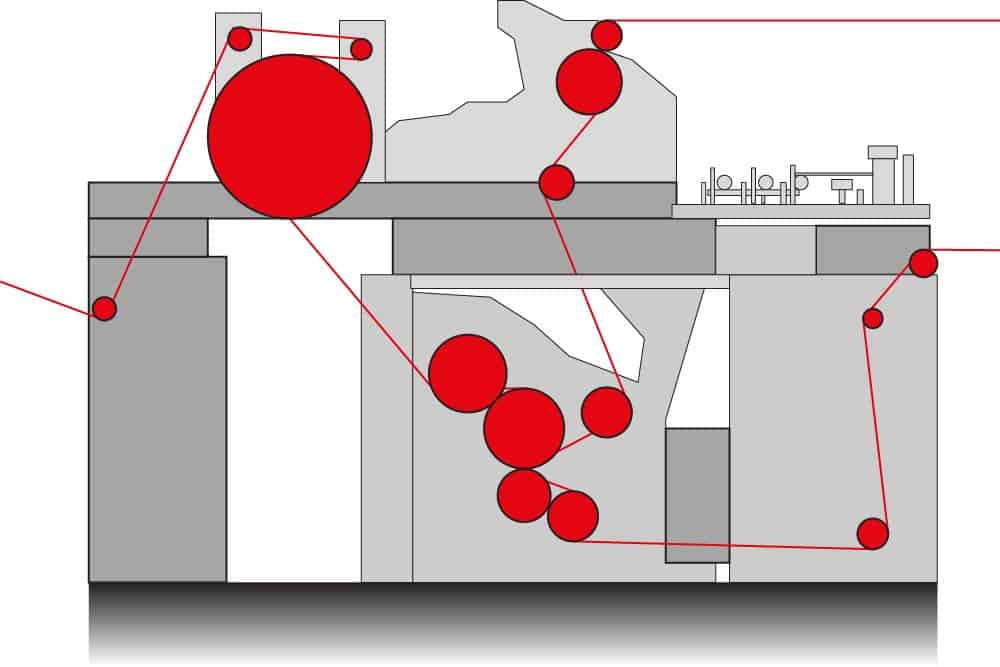

The Smart SF5-Belt SingleFacer is a quick flute change cassette machine, housed in a heavy-duty cast-iron frame. Fosber’s pressure-belt design merges innovation and reliability into one machine.

The Smart SF5 is a negative pressure machine and uses a Teflon coated belt. The Teflon coating increases belt life and prevents starch build-up on the belt. The design of the machine allows for belt replacement to be completed safely and efficiently. Flute change can also be completed efficiently using steam quick disconnects for a safe and reliable machine. All Smart SF5’s have automatic controls for wrap arm positioning, steam pressure, steam shower and glue gaps.

The cost of ownership is reduced with the Smart SF5 machine with the use of the curved hotplates. The curved hotplates allow for automatic variable contact, reduced rotary joints/siphon pipes, and reduced electrical drive/motor systems on pre-heaters. The Smart SF5 has an optional medium and liner water deck system that can be incorporated into the machine for improved heat transfer and higher speeds. The water deck improves heat transfer to paper and produces a quality balanced sheet.

- Width: 98” or 110”

- Speed: 1500 ft/min

- Paper Grades: 10# – 90#

Belt Machine:

- Teflon Coated Cloth Belt (Not Steel)

- 2 Roll System – 1 Motorized and 1 Passive (Heated)

- Easy Maintenance, Access and Fast Belt Replacement

- Automatic Belt Tracking, Alignment and Tension System

Cassette Machine:

- Flute Change in 8 Minutes

- Simple Negative Pressure Design

- All Hydraulics for the Roll Change are Engineered into the Cart

Automation Controls:

- Steam Pressure

- Variable Wrap Positioning

- Glue Gap Metering

- Glue Gap Application

- Glue Dam Positioning

Optional Water Decks:

- Machine Transfers Heat More Efficiently w/Less Energy

- Both Medium & Liner Side

- Creates Balanced Sheets

- Produces High Quality Flat Sheets

Gallery

For more information about the Smart SF5-Belt SingleFacer contact your Sales Representative.