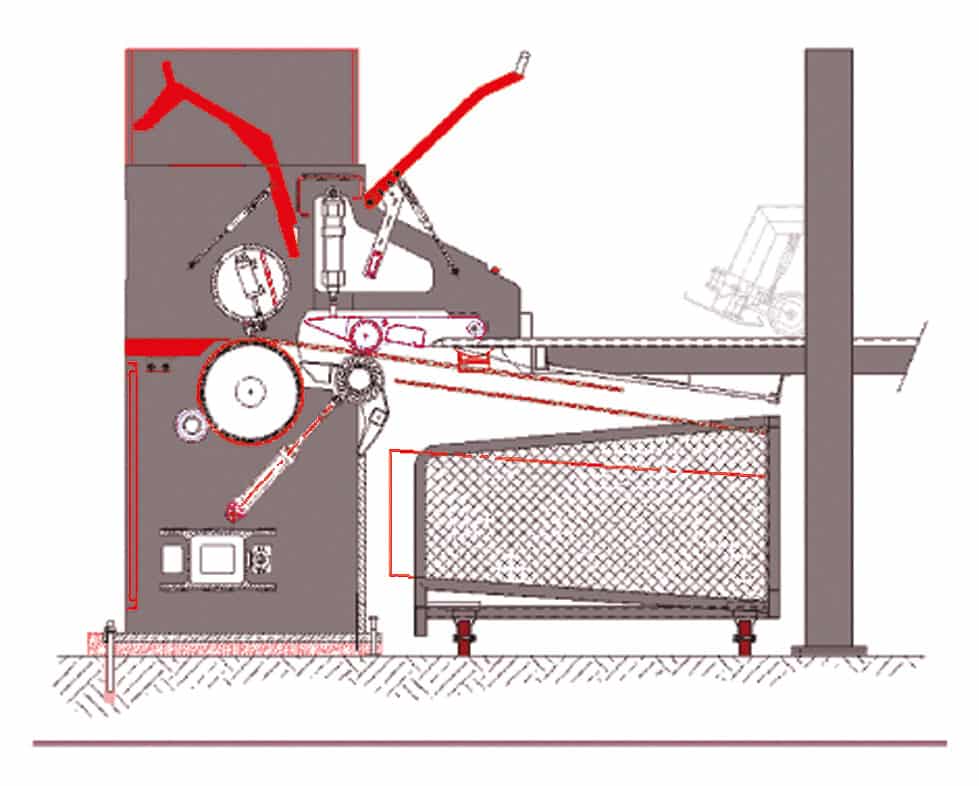

The Rotary Shear 400 is a high-speed machine offering flexibility in configuration, installation, machine features, and single cut speeds up to 1000 ft/min.

This machine utilizes Fosber’s advanced Syncro automatic control for single, continuous, or “No-Gap” order changes. A patented air-cylinder system activates 26 individual blades allowing for constant web flow to the knife. “No-Gap” and single cut can be accomplished at 1000 ft/min and continuous cut at 820 ft/min.

The Rotary Shear 400 provides maximum options for your current needs and allows the most flexibility for future modifications or changes to your corrugator.

- Width: 98″ or 110″

- Speed: 1000 ft/min for “No-Gap” and Single Cut

- Speed: 820 ft/min Continuous Cut (Waste Expulsion)

- Allen-Bradley Electronics

- Compact Design

- Intelligent Guard Monitoring

- “No-Gap” Order Change Advantage:

- No Changing of Measuring Devices

- No High Speed “Tail-out” of the Old Order

- No “Lead-Edge” Jams

- Elimination of Board Skew at “Tail-out”

- Better Shingling on the Stacker

Gallery

For more information about the Constant System Rotary Shear contact your Sales Representative.